Giving priority to quality, safety, and technical management, YPP Corporation has been providing Total Engineering Solution by performing works with the most economical and optimized methods. By fostering the ability to cope with rapidly changing market and demand of customers efficiently through coexisting management for the development of stockholders, employees, and cooperative companies, we promise to be the most reliable business partner understanding and satisfying the requests of customers.

Design of Fluidic Machinery, Equipment, and System

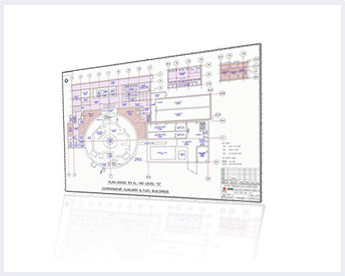

System Design and Documentation of Specification/Design Drawing/Certification

- Design evaluation and conceptual design for the substitution of post accident sampling system(PASS)

- Conceptual design of safety-related air distribution system(Kori unit 1)

- System design and simulation of test facility for high temperature and pressure (340℃, 230bar) steam service

- Design of construction piping, machinery, and electricity(Kori uni 3&4)

- Reliability evaluation of transformer protection device

Design of Pressure Vessel and Equipment

- Design, manufacture, and startup of pressure vessel for high temperature and pressure (310℃, 200bar) steam and water service

- Design modification for the safety classification change of pressurizer power operated relief valve(PORV) for Kori unit 3&4 and Yonggwang unit 1&2

- Design review of test requirement for main steam safety valve (Kori unit 3&4/Uljin unit 1&2)

- Participation in design review and source inspection of steam generator and feed water booster pump for Kori unit 1

- Design review and source inspection of low pressure turbine for Kori unit 1,2,3&4(Switzerland)

- ECCS passive strainer design development(BHI)

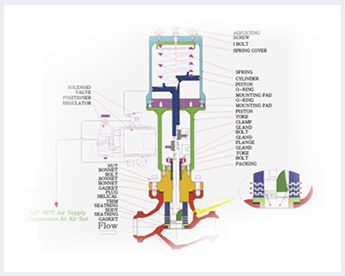

Design and Manufacture of Valve

- Design and manufacture of MOV of 4″, 600# Gate (Wolsung unit 1&2)

- Design evaluation of level control valve of 4″, 1500# for degasser condenser (Wolsung unit 3&4)

- Design and manufacture of precision control valve of 4″, 600# for high differential pressure service for Samcheonpo thermal power plant

- Design and manufacture of diaphragm type on-off valve (Uichin unit 1&2)

- Design modification of pressurizer power operated relief valve(PORV) (Yonggwang unit 3&4)

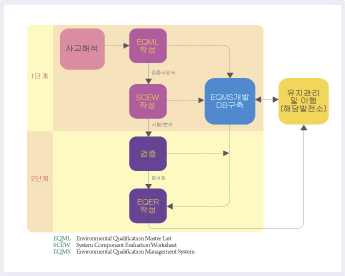

Environmental/Seismic Qualification and Safety Evaluation

- Environmental Qualification(EQ) phase Ⅰ service(Yonggwang unit 1&2, Kori unit 3&4)

- Environmental Qualification(EQ) phase Ⅱ service(Yonggwang unit 1&2, Kori unit 3&4)

- Construction of environmental qualification management system(EQML)(Yonggwang unit 1&2)

- Performance evaluation service for environmental/electric equipment(Kori unit 3&4)

- Periodic safety review(environmental qualification) service(Yonggwang unit 3&4)

- Safety performance evaluation for safety class pump/valve(Yonggwang unit 3&4)

- Documentation of environmental qualification master list and cable line list(Kori unit 3&4)

- Integrity evaluation of paints inside containment(Kori unit 1)

- Performance evaluation of WH type nuclear power plant’s ECCS recirculation sump (Kori unit 2,3&4, Yonggwang unit 1&2)

- Performance evaluation of fire wall penetration(Kori unit 2)

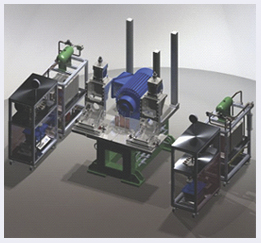

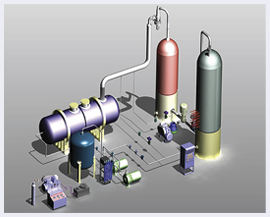

Design and Manufacture of Test Facilities

- Detailed design of performance certification facility of valve/pump for high temperature and pressure service(KEPRI)

- Detailed design/manufacture of performance test facility prototype for pressurizer safety valve(NETEC)

- Design and manufacture of automatic/remote/precise length measurement system(NETEC)

- Design and manufacture of fluid leakage test device (Power System Engineering)

- Design and manufacture of flow inducing vibration simulator(KEPRI)

- Design and manufacture of acoustic test device for valve leakage measurement(KEPRI)

- Manufacture of test facility for AOV dynamic characteristics (Hanvit Power Service)

- Air compressor durability test facility(WABCO Korea)

- Design/Manufacture of test device, consol, pump and training facility of abnormal fluid conditions (Yonggwang nuclear power site)

- Air compressor durability test facility(exported to WABCO China)

- Turbo Booster Unit(WABCO Korea)

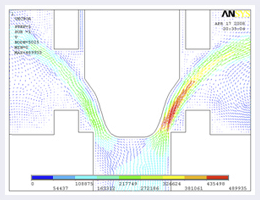

Flow and Structure Analysis

- Integrity evaluation of isolation piping filled with water (Kori unit 1)

- RVI CVAP flow and structure analysis (Shin-Kori unit 4)

- Development of design and manufacture technology for reactor ECCS passive strainer

- Stress analysis of piping and support of test facility for pressurizer safety valve

- Localization of AOV actuator

- Seismic safety evaluation for pressurizer spray water control valve

- Performance evaluation, design, and flow and structure analysis for main steam drain valve (Yonggwang unit 1&2)

- Performance evaluation and design modification for 44 valves including AB-LV429 and AC-HV015 (Yonggwang unit 1&2)

- RVI CVAP flow and structure analysis (Kori unit 4)

Design, Startup, Operation, and Maintenance of Plant

- Operation of reactor/turbine field and main control room (Kori unit 1,2,3&4)

- Startup and commercial operation (Kori unit 2,3&4)

- Design and installation inspection of system, piping, and equipment in nuclear power plants (Kori unit 1,2,3&4)

- Replacement work and inspection of steam generator for Kori unit 1 (Machinery, civil engineering, and instrumentation and control)

- Maintenance of reactor instrumentation and control facility (Kori unit 1&2)

- Maintenance of turbine instrumentation and control facility (Kori unit 1&2)

- Replacement work and inspection of low pressure turbine (equipment and instrumentation and control) (Kori unit 1,2,3&4)

- Installation service of steam generator leakage monitor(SGLM) (Kori unit 1&2)

- Inspection and calibration of reactor and turbine control valve (Kori unit 1&2)

- Replacement work of reactor and turbine process control facility (Kori unit 1)

- Documentation of startup procedure(from cold shutdown to full power)

- Documentation of shutdown procedure(full power to cold shutdown)

- Replacement work of station computers (Kori unit 3&4)

- Design of main control center (Shin-Kori unit 3&4)

- Design reinforcement service for the facilities to cope with station blackout for Yonggwang and Uljin nuclear power plants

- Replacement work of main control room for Kori unit 1

Construction of Nuclear Quality Assurance System and Source Inspection

- Construction of nuclear quality system and technical support (17 companies including YOUNG TECH)

- Participation in 17 courses of quality training including practical business class for nuclear quality assurance (6 persons completed)

- Source inspection of MSIV for Kori unit 3&4 (U.S. B&W)

- Construction of nuclear quality system(DKT)

- Quality assurance audit and surveillance for nuclear power plants (36 times including for Wolsung unit 1)

- Source inspection of nuclear power plants’ equipment including steam generator for more than 300 times