Test facilities for fluidic machinery are designed reliably and efficiently based on specialized and proven engineering technology accumulated over service periods of decades in nuclear power plants under operation and construction and in industrial facilities.

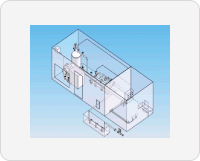

Performance Test Facility for High Temperature and Pressure Valves and Pumps

This facility is developed to test the performance of the valves and pumps for high temperature and pressure serviced in NSSS and BOP of nuclear power plant, and is designed in accordance with the requirements of KEPIC MF, ASME QME-1 and PTC code.

- Design Pressure: 300 kgf/㎠

- Design Temperature: 371 ℃

- Service Pressure: 207 kgf/㎠

- Uncertainty: less than ±1%

- Service Temperature: 300 ℃

- Design Flowrate: 106 ㎥/min

- Fluid Used: Water, Nitrogen

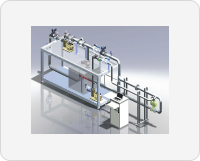

Performance Test Facility for High Temperature and Pressure Valves

This facility is developed to measure the leak rate of valve by sing ultrasonic wave and temperature change and by generating high temperature and pressure steam.

- Design Pressure: 130kgf/㎠

- Design Temperature: 340℃

- Service Pressure: 110kgf/㎠

- Service Temperature: 300℃

- Design Flowrate: 0.4㎥/min

- Fluid Used: Water, Nitrogen

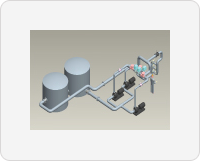

Performance Test Facility for Pressurizer Safety Valve

This facility is used to verify the opening set point, working fluid volume, and dynamic characteristic of loop seal and makes it possible to optimize the opening set point.

- Design Pressure: 220 kgf/㎠

- Design Temperature: 380 ℃

- Service Pressure: 220 kgf/㎠

- Service Temperature: 366 ℃

- Design Flowrate: 420,000 lb/hr

- Fluid Used: Water, Nitrogen

- Uncertainty: less than ±1%

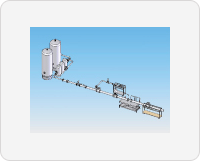

Water Hammer Generating Facility

This facility simulates a water hammer condition occurring when flowing fluid inside pipe is blocked abruptly and evaluates the power of water hammer by adjusting flow direction and pressure. The water hammer usually is accompanied with noise and vibration and may damage the equipments and instruments equipped with piping.

- Design Pressure: 12 kgf/㎠

- Design Temperature: 100℃

- Design Flow Rate: 40㎥/hr

- Fluid Used: Water

Low Temperature Performance Test Facility for Valves

This facility is used to test and diagnose the performance of precise control valve and actuator, measures the control power of flowrate and displacement including Cv. The analysis of test results indicates necessity of maintenance.

- Design Pressure: 15kgf/㎠

- Uncertainty: less than ±1%

Durability Test Facility for Air Compressor

This facility is designed to test normal and abnormal operating condition so as to contribute to ensure the qualify of air compressor.

- Design Pressure: 25kgf/㎠

- Design Temperature: 360℃

Training Facility of Abnormal Fluid Conditions

This facility realized the fluid abnormal conditions such as cavitations, water hammering, pump’s Run-out, and shutoff head and is used for training aid.

- Cavitation Realizable

- Water Hammering Realizable

- Pump Run-out Realizable

- Fluid Used: Water

Valve Performance Test Facility Using Air

This facility is used to test and diagnose the performance of precise control valve, and measures the differential pressure, flow rate, control power. The measured results are compared with design valves to diagnose the performance of control valve.

- Design Pressure: 9kgf/㎠

- Main Pipe 8", ANSI class 300

- Aux. Pipe 3", ANSI class 300