YPP Corporation, which prioritizes quality, safety and technology management, provides Total Engineering Solution by applying proven technology based on international technical standards and performing its tasks in a systematic way.

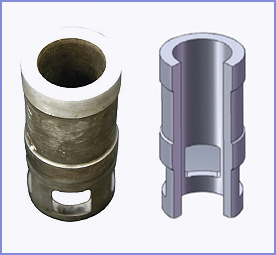

CAGE

Characteristics

- Applied to valve for high flow and medium & low pressure service

- Suitable for general service

- Cage type and plug selected according to flow characteristics

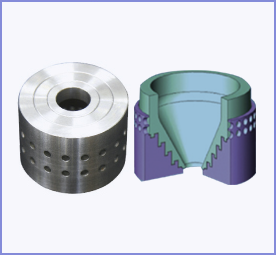

HARMONY 1000

Characteristics

- Applied to valve for high flow and medium & low pressure service

- Improved durability in shut-off condition

- Flow limit at initial valve opening and protection of seat and plug from damage

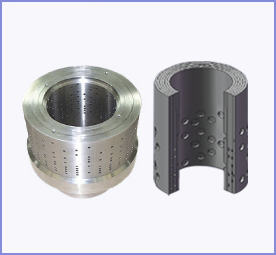

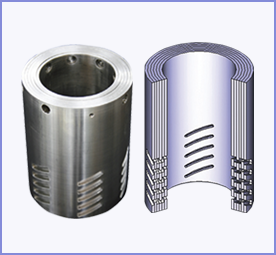

HARMONY 2000

Characteristics

- Applied to valve for high flow and high differential pressure service

- Multi-stage and multi-path trim of cylinder structure

- Anti-noise and anti-cavitation

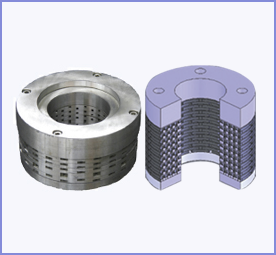

HARMONY 3000

Characteristics

- Suitable to valve for very high pressure and high differential pressure service

- Multi-stage and Multi-path of laminated disk structure

- Anti-noise, anti-erosion and corrosion due to the structural design of flow path cross section

HARMONY 4000(3D Multi-stage Trim)

Characteristics

- 3D Multi-stage Trim developed newly with multi-stage and multi-path structure

- Compact design with optimal performance at various differential pressure conditions

- Precise control capability without flow dead band