Valve leakage diagnosis and repairing service

YPP Corporation' s valve leakage diagnosis technology is applied to the power plant system, the energy related facilities and etc. It provides power increase or efficiency increase by diagnosing the current state of the valve and repairing or replacing the leak valves.

Service method and process

Step 1 >> Within 3 months after kick-off

- Power plant operation data and history check (total output check)

- Diagnosis of valve leakage in boiler and turbine system

- Derivation of performance improvement(output increase) to select target for repair or replacement

- Improvement effect and economic evaluation - Estimation of necessary construction cost, purchase price of equipment

- Estimated profit evaluation (internal rate of return, payback period, etc.)

Step 2 >> Within 7 months after completion of Step 1

- Repair leakage valves and engineering work for replacement valves.

- Manufacture of replacement valves and purchase of Key Parts

- Derivation of performance improvement(output increase) to select target for repair or replacement

- Engineering work for field construction

- Re-diagnosis of improved valve leakage

Work for Step 1 >>

PREPARING PRELIMINARY LISTS ▶ FIELD KICK-OFF MEETING ▶ CONFIRMATION OF TARGET VALVES ▶ FIELD DIAGNOSIS ▶ DATA ANALYSIS ▶ PREPARING TECHNICAL REPORT ▶ ECONOMIC ANALYSIS REPORT

- Preparing preliminary lists/Field kick-off meeting/Evaluation of valve leakage diagnosis

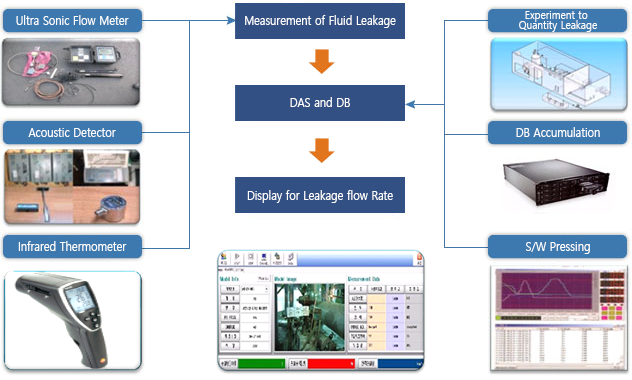

- Field diagnosis : -Application of ‘Development of Quantitative Realtime Fluid Leakage Measurement System Using Ultrasonic and Acoustic Leakage Signal(’05~’08)’ sponsored by MKE and patent No. 10-0894430, ‘Measurement method using fluid leakage measurement device for valves using ultrasonic, acoustic and temperature change’.

- Data analysis and technical reporting -Plan for maintenance work on leakage valves

- Economic Analysis Report - Estimation of necessary construction cost, purchase price of equipment

-Calculation of energy loss amount according to leakage measurement

-Determine maintenance work, establish leakage evaluation criteria, and work methodology.

-Selection of the valves to be replaced sequentially according to leakage degree

- Estimated profit evaluation (internal rate of return, payback period, etc.)

Work for Step 2 >>

DETERMINATION OF REPLACEMENT AND REPAIR VALVES ▶ PREPARING SPECIFICATIONS ▶ COMPUTATIONAL ANALYSIS AND DESIGN DRAWING ▶ MANUFACTURING VALVE AND PARTS ▶ CONSTRUCTION ▶ VALVE REPLACEMENT AND MAINTENANCE ▶ RE-EVALUATION REPORT OF LEAKAGE DIAGNOSIS

- Determination of replacement and maintenance valves based on primary performance results.

- Preparing specification for replacement valve and expected repair parts

- Computational analysis and design drawing -Analysis of valve body, fluid velocity of seat ring and trim, pressure and flow patterns

- Field construction and re-evaluation report of leakage diagnosis -Field installation and construction during maintenance period of power plant

-Analysis of the stress distribution for the combination of operation load using ANSYS, NASTRAN, LS-DYNA, etc, structural soundness verification and design adequacy analysis for interference of parts and design criteria

-Maintenance of leakage valve during maintenance period of power plant

-Measurement leakage of replacement valve during testing period of power plant

Applicable Valves >>

- Valves that remain closed during power plant operation - Valves that vibration occurs

- Valves that cavitation occurs

- Valves that hunting occurs during operation

- Valves frequently clogged by debris in trim or cage

- Valves that noise occurs

- Valves with suspected internal leakage

- Valves with frequent internal maintenance

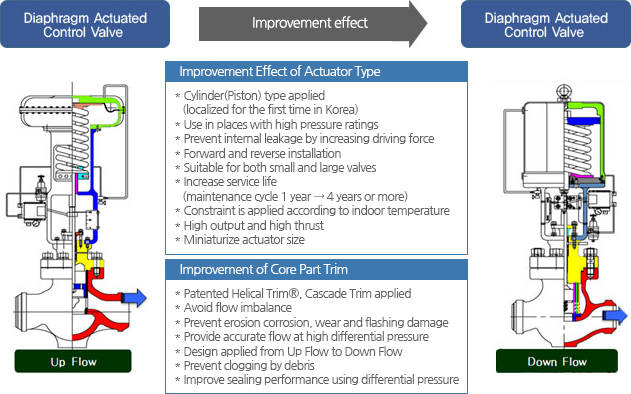

Technical Information(Improvement effect of valve)

YPP Corporation’s valve leakage diagnosis technology is applied to the power plant system. It provides power increase by diagnosing the current state of the valve and repairing or replacing the leak valve(Improvement by applying to about 900 valves of Kori, Yeonggwang, Uljin, Wolsung nuclear power plant, and domestic thermal power plants).

Technical Information (Leakage Measurement Method)

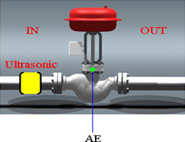

Concept of fluid leakage measurement technique

Effect of fluid leakage measurement technique

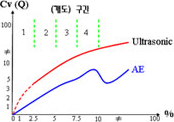

- Both Ultrasonic and AE(Acoustic Emission) are applicable to the field of power plants by applying Multi-Measuring technology because effective measurement values can be obtained in the inherent leakage characteristics due to valve damage.

- AE: It is useful to judge leakage when 1 ~ 2% interval(leakage amount is small) (Unit: dB, J, l / s)

- △T: Leakage can be clearly identified with △ T when 5% or more interval(leakage amount is large) Leakage can be clearly identified with △T (Determination using tentacle, infrared temperature measurement or thermal imaging camera)

| Valve Opening Rate | Measurement Method | Remark |

|---|---|---|

| 0%~2% | AE | Only check for damage(No quantification required) |

| 2%~5% | AE + Ultrasonic | Multi-Measuring |

| +5% | Ultrasonic + T | Multi-Measuring |