YPP Corporation provides total engineering service(design, manufacture, installation, operation, and evaluation) based on field oriented nuclear plant technology with powder plants and plant facilities.

Evaluation of Valve Internal Leakage and Providing the Maintenance Guidance

The internal leakage from closed valve causes damage to equipments and degrades thermal efficiency in high temperature and high differential pressure conditions during normal operation. The internal leakage is detected precisely using patented unique technology and the maintenance guidance is provided.

- Precise measurement of internal leakage rate during normal operation(establishment of preventive maintenance and repair plan)

- Precise measurement of internal leakage rate just after planned preventive maintenance(evaluation of valve integrity and verification of maintenance quality)

- Measuring band : 0.001~10 l/s

- Uncertainty : less than ±1%

Evaluation of Spent Fuel Pool Cooling Capacity

When fuel assemblies are taken out from reactor and moved into the spent fuel pool earlier to shorten the overhaul period, it is expected that spent fuel pool cooling capacity is not sufficient to remove decay heat from spent fuel assemblies. In order to solve the problem, the optimized design change and operating scheme are proposed.

- Calculation of heat exchange capacity to be replaced

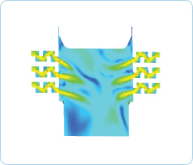

- Analysis of fluid movement and temperature distribution in spent fuel pool using CFD

- Evaluating of cooling capacity effected by earlier spent fuel withdrawal from reactor

- Evaluation of heat exchanger capacity and type to be replaced and constructability / manufacturability for new heat exchanger installation

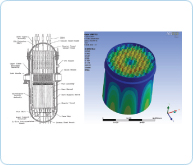

Shin Kori Unit 4 Reactor Vessel Internal Comprehensive Vibration Assessment Program (RVI CVAP)

The analysis for coolant flow and internal vibration inside reactor, and structure are performed to determine the natural frequency and vibration mode, deformation rate and strain in RVI CVAP with correct measurement parameters and location within allowable test limits.

- Establishment of RVI CVAP flow and structural analysis methodology

- Flow analysis to determine periodic and irregular hydraulic load

- Vibration analysis to natural frequency and vibration mode

- Structural analysis for deformation rate and strain of structure

- Conceptual design of RVI CVAP measurement system

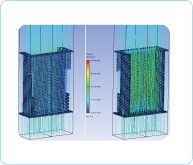

ECCS Passive Strainer Design Development

The ECCS passive strainer design is developed for filtering the debris generated due to impingement impact in case of Loss of Coolant Accident(LOCA) so that the safety injection pump has sufficient NPSH to circulate cooling water into core continuously under any worst circumstance. This newly developed ECCS passive strainer unit is to be installed in OPR 1000.

- Development of requirements and conceptual design of the ECCS passive strainer

- Development of detailed design and manufacturing specification of the ECCS passive strainer

- Layout design development for applying the unit to OPR 1000

Performance Evaluation and Design Improvement of Yonggwang Unit 1&2 Mainsteam Condensate Drain Valve

Repeated internal leakage in mainsteam condensate drain valve causes damage to trim and degrades thermal efficiency. Performance evaluation is performed to determine the necessity of replacement or improvement for 46 unreliable drainage valves. Repeated internal leakage in mainsteam condensate drain valve causes.

- Design check/review of mainsteam condensate drain valves

- Performance evaluation of drain valves vulnerable to leakage

- Development of basic design of improved valve

- Performance and dynamic characteristic tests, manufacturing of prototype valve

- Integrity and economic evaluation for the improved valve

Design Evaluation and Elimination of Post Accident Sampling System (PASS)

The elimination of PASS due to the reduced usefulness of post accident sampling decreases operational burden such as radiation exposure, periodic surveillance, and maintenance. Instead it increases the operability and economy in the pressurized water reactor type power plant.

- Evaluation of post accident sampling requirements

- Review of PASS elimination methods

- Economic study of PASS elimination

- Preparation of topical report and other documents necessary for licensing

Verification of Equipment Qualification of Nuclear Power Plant

It is verified that safety related equipment are qualified to function properly in severe environmental conditions during and after design basis accident in accordance with Periodic Safety Review(PSR) and applicable licensing regulatory requirements.

- Establishment for verification system of equipment environmental qualification

- Preparation of list for equipments subject to environmental qualification and collection of qualification documents

- Environmental qualification of equipments that fail in the verification of qualification

- Improvement of environmental condition for equipments that fail in qualification